SIGA Machine Tool Co., Ltd. provides specialized machine tools, spindles, feed units, and other products that contribute to improving customer productivity and have received high praise over the years.

This also applies to any malfunctions or maintenance issues. SIGA Machine Tool Co., Ltd. places great emphasis on product maintenance and support, providing prompt assistance to ensure long-term stable usage for customers.

- Specialized machine tools: In case of any malfunctions that occur due to long-term operation, our engineers will respond promptly and provide repair support. If your maintenance department is responsible, we will promptly supply the necessary replacement parts.

- Precision units: If you have units that require overhaul or repair, please send them to our company. We will quickly repair them and deliver them in a ready-to-use condition. If there are suspected issues with your usage method, we will propose the cause and improvement measures.

- Other manufacturers' machines/units: If you are facing difficulties in finding a repair service for your equipment, please consult SIGA Machine Tool Co., Ltd. We will do our best to accommodate your needs with our extensive expertise and experience. (For spindles, please refer below)

Spindles and other units provided by SIGA Machine Tool Co., Ltd. have been highly praised by many customers for their excellent durability.

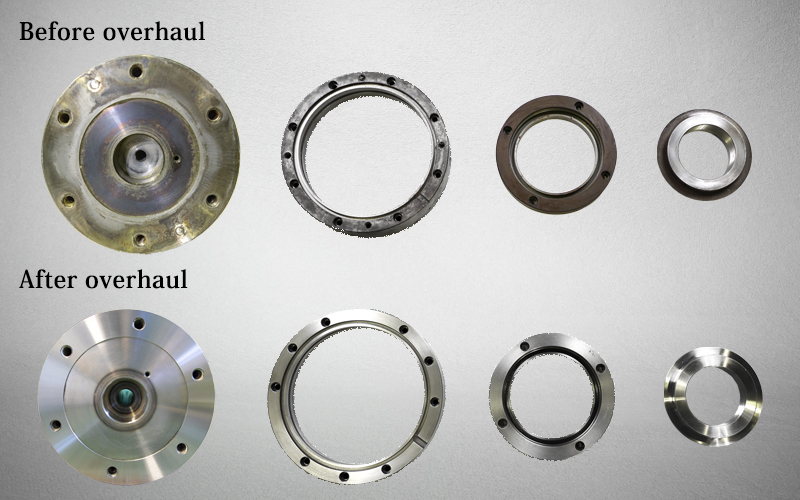

However, extended usage may cause wear and deterioration of consumable parts such as bearings. Regular overhauls are necessary to maintain machining precision.

Our company has established a system to repair spindles as quickly as possible. We aim to minimize the downtime of your production line and contribute to reducing environmental impact through effective resource utilization.

At SIGA Machine Tool Co., Ltd., spindle overhauls are performed following the steps outlined below:

- Disassembly and cleaning: The spindle is disassembled, and each component is thoroughly cleaned.

- Inspection and measurement: The condition of each component is inspected to identify the cause of any malfunction. An estimate is provided at this stage.

- Replacement and repair: If abnormalities or defects are found, parts are replaced or repaired.

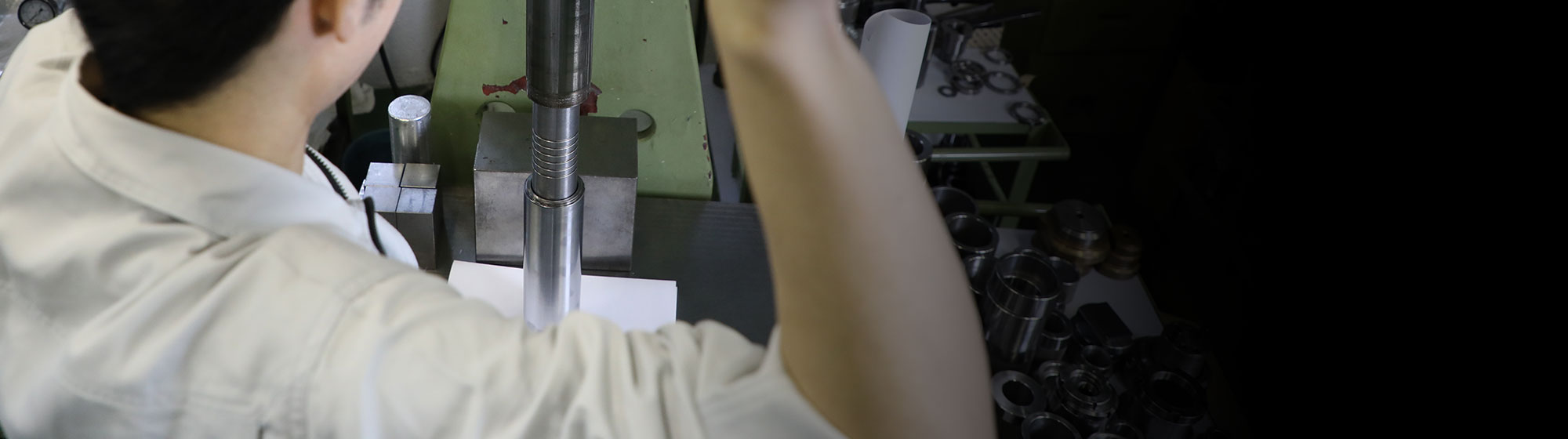

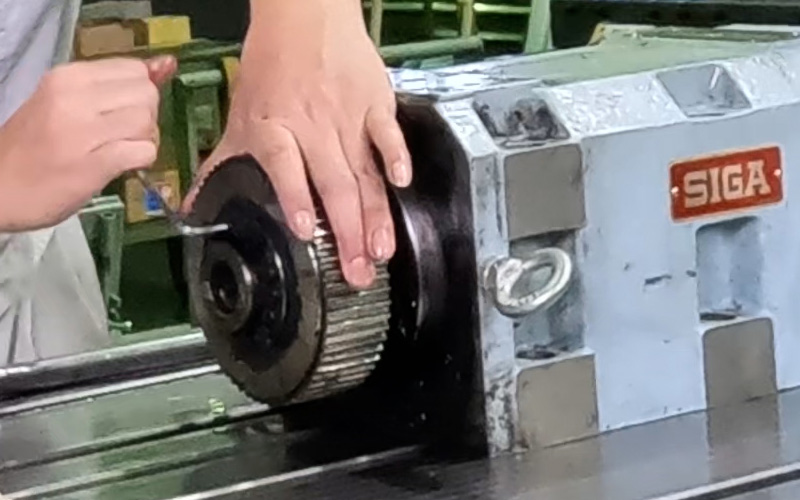

- Assembly and adjustment: Skilled technicians assemble the parts after repairs and replacements are completed.

- Rotation test and delivery: A rotation test is conducted over several days to confirm the required performance, and the spindle is delivered to the customer with the test data.

SIGA Machine Tool Co., Ltd. conducts spindle overhauls with meticulous workmanship by technicians who are well-versed in spindles, ensuring high-quality product delivery.

We have extensive experience not only in repairing our own products but also in handling spindles from other manufacturers.

If you have any concerns or inquiries regarding spindle overhauls, please feel free to consult SIGA Machine Tool Co., Ltd.

We provide tailored support to meet your needs and assist in ensuring the stable operation of your spindles.